The experience gained in the field of composting provides us with a consolidated and solid foundation to further develop the biological processing of solid organic waste under the new paradigm: the conversion of waste into raw materials (from waste to product) through Solid-State Fermentation (SSF). The research group began working on this new line of research in 2010 with the aim of obtaining a wide range of value-added products from different waste materials. For example, waste from oil refining, cow hair from the leather industry, or orange peel, from which enzymes (lipases, proteases, cellulases), biosurfactants, or biopesticides can be obtained. We are working to obtain biofuels and other chemical compounds. The possibilities seem endless. That is why research in the field of SSF is increasing.

However, the main challenge remains scaling up to an industrial level. Our research, based on our successful knowledge of composting at an industrial scale, aims to achieve a reliable and easily scalable SSF process. At the same time, we focus on the production of new products and their use in both environmental applications and green chemistry processes.

The bio-products we are currently researching include biosurfactants, plant biostimulants, and biopesticides.

Biosurfactants

In the GICOM group we have explored the production of biosurfactants through the bioconversion of food industry waste by solid state fermentation. Specifically, we have studied the production of sophorolipids, a glycolipid with multiple applications in environmental resortation, agriculture, cleaning or personal hygiene products, and the cosmetics industry, among others. This compound can be produced by fermentation of substrates rich in oils and / or sugars. For example, filter cake from the edible oil refining industries (sunflower, corn, etc.) has an enormous potential as a source of hydrophobic carbon for the yeast Starmerella bombicola, one of the best known producer of these biosurfactants. Production from urban or industrial waste hydrolysates has also been shown to be viable. By optimizing process conditions and selecting laboratory-scale media, we achieved promising productivity of approximately 3 g of SL per liter per day. The process has been successfully scaled-up to an actual volume of 60 liters. In order to develop this process on a commercial scale, we are improving the procedures for recovering SLs from the solid matrix and exploring advanced operation and process control strategies for successful scaling-up. In addition, we are conducting economic and environmental feasibility studies of the process. The developed process can be extrapolated to the production of other glycolipid biosurfactants produced by yeasts on analogous carbon sources.

Biopesticides

Biocontrol agents can totally or partially replace traditional chemical pesticides, they are effective on a considerable number of pests, without having harmful effects on humans, animals or the ecosystem. Some of these biopesticides are of microbial origin, produced by bacteria and fungi. These microorganisms can grow, under controlled conditions, on solid substrates through solid state fermentation. This allows to use waste materials as a substrate, reducing the production cost and becoming a way for waste valorization.

Examples of biopesticides are: Bacillus thuringiensis that is a bacteriathat produces an endotoxin that affects the digestive tract of the larvae of some pest insects. Beauveria bassiana is an entomopathogenic fungus with lethal effects on numerous pests while Trichoderma harzianum has shown fungicidal effects. All three microorganisms are currently marketed as the basis of different biopesticide products.

The Composting Research Group (GICOM) works with Bacillus thuringiensis, Beauveria bassiana and Trichoderma harzianum using waste from various sources to produce both, a compound with a biopesticidal effect and/or a liquid extract with these properties. We are working with substrates such as agro-industrial waste (rice husk, waste fibers from vegetable drinks production derived from rice or soy, bagasse from beer production), as well as pruning waste and organic fraction of municipal waste from selective collection systems. The process was successfully carried out on a semi-pilot scale, in 22L reactors in the case of fungi and up to 290L in the case of bacteria.

Biostimulants

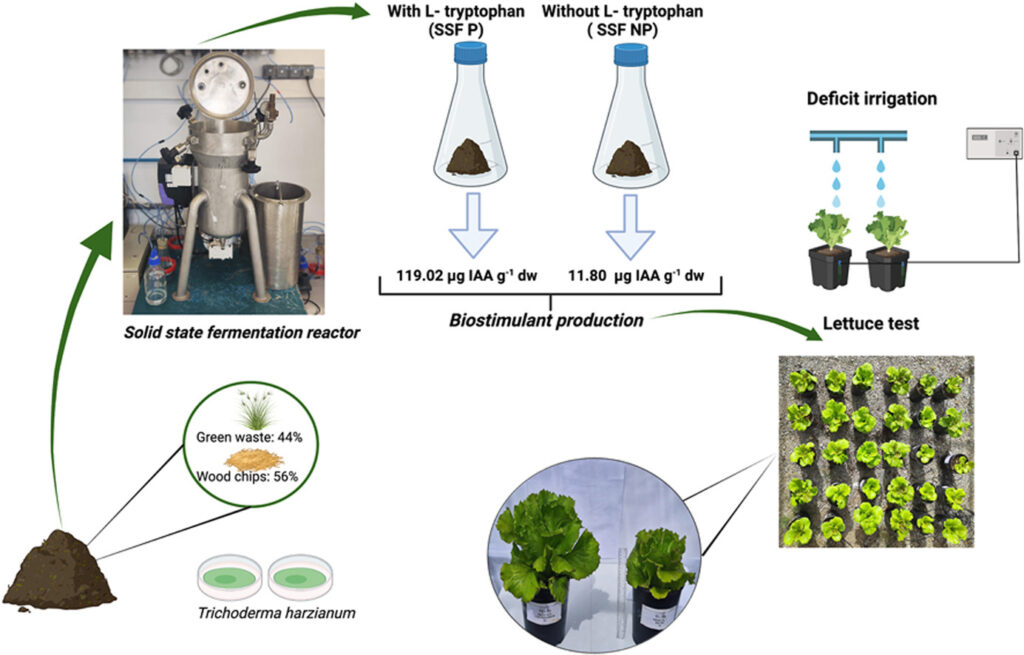

In the context of improving sustainable agriculture, biostimulants play a promising role. Biostimulant is a product that stimulates plant growth, by improving the following characteristics: nutrient use efficiency, tolerance resistance to biotic and abiotic stress, and availability of confined nutrients in the soil or rhizosphere. A wide range of substances as well as microorganisms can be utilized as biostimulants. Among them, the fungus Trichoderma strains, have been predominantly used as biostimulants for their capacity to control the fungal phytopathogens and improving plant tolerance against abiotic stresses.

Auxin is a plant hormone that can be produced by plants and microorganisms. Specifically, auxin is one of the metabolites produced by the fungi as a mediator to interact with the plant. Indole-3-acetic acid (IAA) is the most common form of auxin.

The Composting Research Group (GICOM) is working with Trichoderma harzianum for the production of IAA using green wasteas as substrate.